Piedmont Electric Motor

Ergonomics

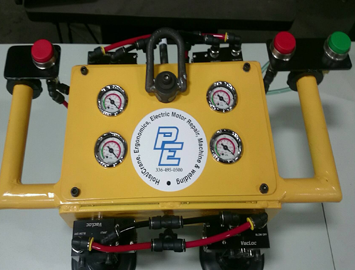

Piedmont Ergonomics

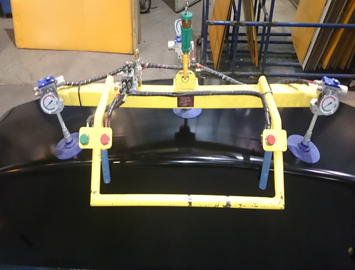

We provide workplace solutions for your company's troubled areas to help reduce worker injuries and insurance costs. Whether you are bring parts to or from an assembly line, moving rolls, or moving boxes, we can provide a custom solution for you. Our custom Below the Hook Fixtures are built according to ASME B30.20 while working closely with your safety team, engineering, and line operators.

OSHA recommends that operators lift no more than 50 pounds repetitively, but a lot of companies set their limit at 35 pounds for an 8-hour shift.